People throughout the UK are eager to unwind and take a well-earned holiday break as Christmas draws near but be aware of workplace accidents . No one wants to get hurt or have an accident at any time of year, but especially during the holiday season, so let’s not let the Twelve Days of Christmas turn into the Twelve Workplace Hazards of Christmas!

Research emphasises the risks of the Festive season at work when individuals are rushing around getting ready for the holidays. Here are some of the twelve most common workplace accidents during the festive period for you to avoid.

1. Christmas Trees

Around 1,000 people in the UK suffer injuries from Christmas trees each year. Most accidents occur when people reach up to secure ornaments to taller branches.

When hanging fairy lights, look for frayed cables or broken fittings; discard any damaged ones to reduce the risk of fire or electrocution. Never water a real Christmas tree with the lights on if you have one in your workplace.

2. Weather

The cold and the rain can create significant hazards. With the holidays comes an increased footfall into shops, hotels, and restaurants. The HSE cautions businesses with tiled entrances that consumers are in more danger on rainy days because water is tracked in on people’s shoes. Installing non-slip rubber entrance matting is advised to help reduce accidents.

Those working outside need to have PPE equipment provided to help them combat the lower temperatures.

3. Temps and Seasonal Staff

In the weeks leading up to Christmas, many businesses use temporary labour. Because of the rapid rush of new hires, they won’t be familiar with the workplace procedures of the organisation. To reduce the risk of workplace accidents, seasonal employees must undergo the same health and safety training as every other worker.

4. Travel

32% of individuals have fallen on ice in the weeks leading up to Christmas. If you know it will be below freezing, take care when driving, make sure you know when the final train is, or reserve a licenced taxi in advance. For the trip home, pack a pair of boots or flat shoes.

5. Back injuries

The festive season is becoming synonymous with back issues. Make sure you are trained in the proper technique if you work in a position that needs a lot of heavy lifting, especially during the festive season.

The same goes for employers, who are responsible for their staff members’ safety at all times while they are at work. This involves ensuring they are trained in the appropriate methods and are aware of fundamental health and safety procedures so they can do their duties safely.

6. Falls

2.6 million individuals fall each year while putting up holiday decorations, but whatever the cause, falling is a significant source of injury throughout the holiday season.

Stay careful and only stand on objects that are intended to help you reach higher, such as a ladder that is leaning up against a solid surface and is held by a second person at the bottom for additional stability.

7. Drinking Alcohol

Indulging in a festive tipple might feel like a Christmas tradition, but for some people, consuming too much could be disastrous.

If you’re planning a ‘work do’ and want to avoid workplace accidents, make sure your employees are not in danger of turning up to their shift the next day still under the influence.

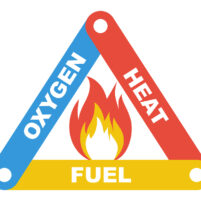

8. Fire Risks

There are higher risks of fires and electrocutions in the workplace when there are more decorations. Employers should ensure that employees required to hang electrical decorations have the necessary training and safety gear to do so. Businesses should also watch out that there aren’t too many decorations plugged into the outlets around a store or workplace. Companies should use an electrician if necessary to ensure that outlets can support the power requirements of decorations.

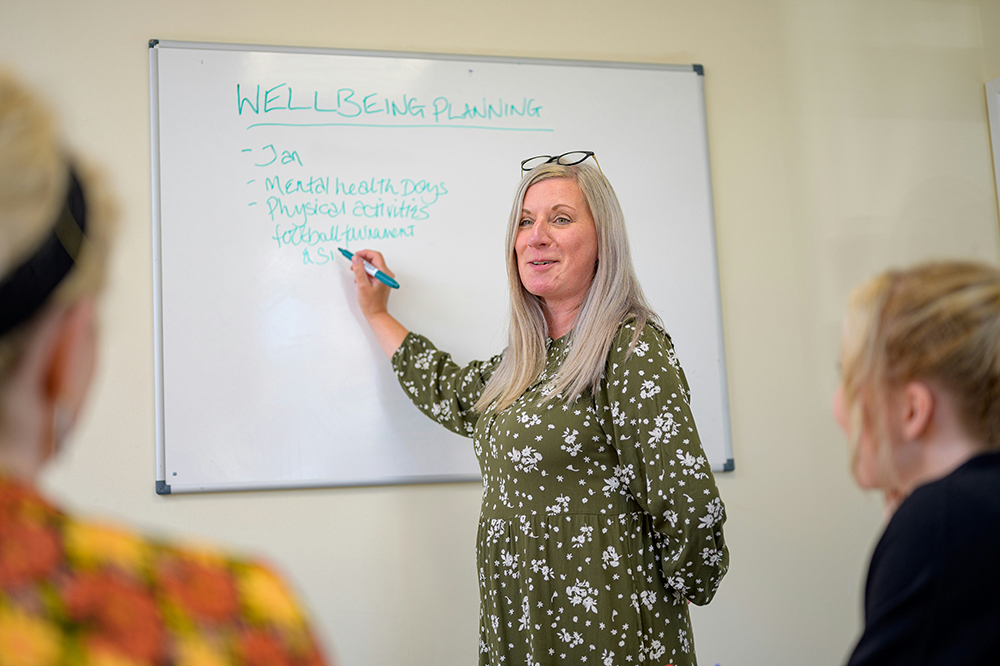

9. Stress

The rush to reach performance targets for both individual employees and departments, as well as for businesses as a whole, makes the festive season one of the busiest times of the year. Sometimes workers feel compelled to work overtime, especially if they are taking holiday time. Employees under work-related stress may become disengaged from their tasks, significantly increasing the likelihood of accidents brought on by exhaustion or distraction. Stress at work itself can harm employees physically and psychologically.

10. Bar Injuries

Over the holiday season, there is a greater demand for bartenders and servers, which entails additional hazards. The most frequent injuries are slips and falls because, during busy hours, a bar’s floor is frequently covered in spilled beverages, melting ice, and other debris.

Without safety mats, employees risk slipping and hurting their backs, heads, and joints. Rushing through the process of picking up and cleaning empty glasses can result in breakages and the risk of bar staff members cutting themselves. Risks can be decreased by using high-quality bar drainage tiles with an anti-slip coating.

11. Festive Food

Food is a common cause of Christmas mishaps; and many a holiday meal has led to some sort of catastrophe. Burns from hot food and slipping on food dumped on the floor are frequent occurrences during Christmas parties held at your place of employment.

At the office party, an estimated 3.7 million people have accidentally spilled food or drink on someone else.

12. Peer Pressure

Even if everyone is enjoying a drink, resist the urge to give in to pressure from your friends. We’ve all been influenced by others to do something ridiculous but resist the urge to dance on the desk.

In the UK, falls from height at work result in about 80 serious injuries per year, including broken limbs and fractured skulls, and 230 absences lasting longer than three days.